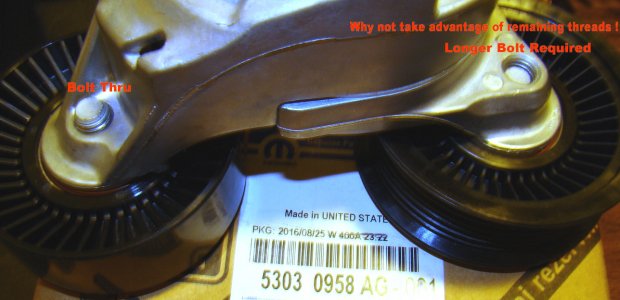

Jeep dealer is going to be advised about how their steel bolt and aluminum threads on the ribbed pulley is weak & needs to be strengthened- "updated" more like now... heli-coiled !

There are no instructions about the range in motion or pushing it too far to get belt on !

So ya I'm now on my second new AG tensioner, as the 15mm bolt stripped interior threads during installation.

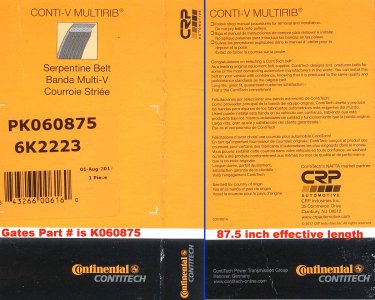

To avoid stripping, a longer belt for this job will be required.

62541[/ATTACH]"]

You must be registered for see images attach

In my second tensioner attempt today using the standard belt, I was successful, however, another person had to assist in stretching the belt on, as to not push things too far.

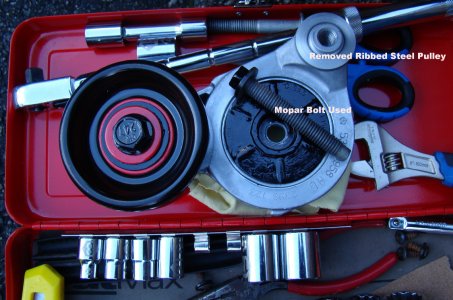

It should also be noted that for ease of installation, as the bolt hole is somewhat covered by the larger pulley, It is easier to just remove the ribbed pulley, and then install the tensioner center bolt while the pulley is off.

62543[/ATTACH]"]

You must be registered for see images attach

Back up & running now with the steel pulleys finally.

62545[/ATTACH]"]

You must be registered for see images attach